Media Beginning to Notice Food Supply Chain “Perfect Storm” as It Arrives

Quite remarkably this ABC report on empty shelves is not far away from outlining the truth. They are still obfuscating some of the predictable reasons, and they completely ignore the vaccination mandate aspect that is going to worsen the issue, but they are nibbling the edges, nonetheless.

The backward-looking comparative statistics they cite, “15% shortage for food and beverages” overall, are nonsense. The severity of unavailable products is much higher than that. You will note from your own store visits the most unavailable products are the manufactured food and heavily processed products.

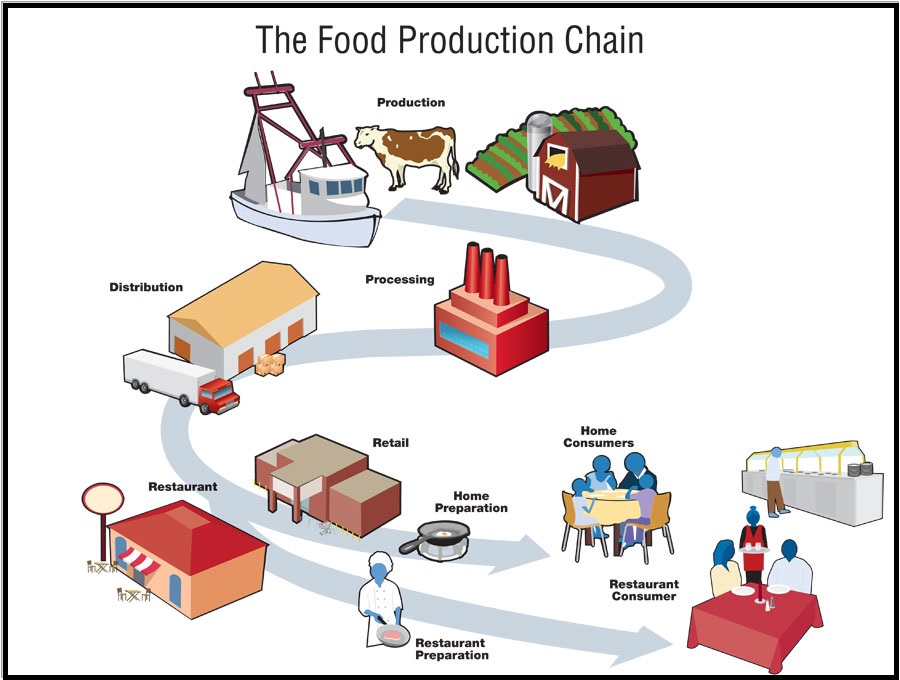

The raw material shortage inside the retail manufacturing supply chain path, combined with the increased demand on those manufactured sectors, is the direct cause of the manufactured food shortage. {Go Deep} [Example: a high demand for citric acid means complex foods that use citrus flavorings (ie. sports drinks) are in short supply. Chase that backward, and you see shortages in citrus & higher citrus costs, etc.]

Each seemingly small issue creates another small issue, which creates another small issue, which ultimately pokes holes in the supply. Poke enough holes in enough small categories from manufactured condiments to manufactured drinks, to manufactured cereals, pasta, grains, soups, pet foods, and the complex food processing system overall begins to show the larger problem. It’s a system collapse by a thousand paper cuts.

Some well intentioned people will claim the shortage of processed and manufactured food is a good thing, and people should eat more fresh foods and be healthier.

Some well intentioned people will claim the shortage of processed and manufactured food is a good thing, and people should eat more fresh foods and be healthier.

Let me be very frank about this. Without full-service fresh prepared food delivery operating normally (restaurants, hotels, cafeterias, lunchrooms, food trucks, venues etc) there isn’t enough fresh food in the U.S. retail distribution system (grocery chains) to feed 350 million people.

We simply need processed and manufactured foods.

Additionally, many of those manufactured foodstuffs (spices, sauces, etc) are additives to what people call “fresh food” preparation. If you want salt, pepper, olive oil, butter, tomato paste, pasta, flour, etc., you need processed and manufactured food.

As we go into this phase, the ABC report was correct on where these issues will be less noticeable, less fragile. The smaller grocery outlets with closer connections to the field. The closer the grocer is to the farmer, the less fragile they are in this shortage phase. “Grocers” (traditionally defined) will do better than “supermarkets”.

Also think about it like this. Does your grocery store have an in-store bakery? If so, their ability to make bread means they are less susceptible to running out of bread. If processed industrial bakeries experience issues, your in-store bakery may not. You will pay much more, but the product will exist. The key is having knowledge of where the product exists.

On a supermarket basis, the total operational excellence comes into play now. Top shelf field-to-fork operations like Hannaford, HEB, Publix and Wegmans will fare much better than Kroger, Ahold, Giant Eagle, Albertsons, Shop Rite, Meijer, Safeway, Winn Dixie etc. You can see how the former group rely more on fresh product supply chain relationships, and the latter group are weighted heavily toward low-price highly manufactured.

What are you seeing around you?

Resource Material:

Post a Comment