There are two merging inflection points set to hit the public in a few days.

The first, is a much faster collapse in credibility for those who are pushing the vaccine benefit narrative. The second, the more widespread appearance of shortages for food and basic essentials. These two broad narratives are going to merge. CTH will outline the issues as they predictably surface. This outline focuses on the latter, the supply chain angle.

♦ The cross-border vaccination mandate protests by truckers are continuing in Canada and at areas near the U.S-Canada border. The vaccine mandate for the Canadian side began on January 15th. The mandate for the U.S. truckers begins January 22nd. Both groups are currently slow-rolling the protest in/around the border crossings.

A coordinated Trucker Protest on the Canadian side is scheduled for January 23rd {LINK}, coincidentally the same time as a protest rally in Washington DC by members of the healthcare industry. It is not coincidental that retail executives in the grocery industry are starting to prepare people in Canada for major grocery shortages {LINK}.

CANADA – “[…] “Independent grocers are in a myriad of communities in this country where there is no other grocery store,” Sands said. “If those stores close, you’ve got a food security issue.”

Meanwhile, stores are also experiencing a shortage of goods stemming from supply chain issues, including a shortage of truckers, packaging and processing delays and the Canadian winter.

Grocers rely on “just in time” delivery, meaning even transient issues like inclement weather can cause delays and shortages, Retail Council of Canada spokesperson Michelle Wasylyshen said.” (read more)

At the same time the Canadian media start to pick up the downstream consequence discussion – a shortage of products with Canadian retailers – the U.S. side of the equation begins to warn about price increases. This is all connected, yet few in corporate media will elevate high enough to see just how damaging the overall vaccine mandate is in this critical sector that touches everyone’s lives.

The crisis is NOT driven by COVID-19, this crisis is driven by government decision-making around COVID-19. The virus is not causing the immediate supply chain issue.

The crisis is NOT driven by COVID-19, this crisis is driven by government decision-making around COVID-19. The virus is not causing the immediate supply chain issue.

The virus has negligible impact on this issue. It is government intervention, rules and fiats under the guise of COVID-19 that is creating the crisis.

The media blames the former, the media ignores the latter.

…”Only 50% to 60% of U.S. truckers are vaccinated, according to an estimate from the American Trucking Associations.”…

The emphasis is mine:

BLOOMBERG – “New rules requiring truckers to show proof of vaccination when crossing the Canada-U.S. border are cutting into shipping capacity and boosting the cost of hauling everything from broccoli to tomatoes.

The cost of transporting produce out of California and Arizona to Canada jumped 25% last week as fewer trucks are available to cross the border, according to George Pitsikoulis, president and chief executive officer of Montreal-based distributor Canadawide Fruits.

“The lower the supply, the higher the price. Ultimately it’s the consumer that pays for this,” Pitsikoulis said Monday by phone.

Canada implemented new rules on Jan. 15 that require border agents to turn away unvaccinated U.S. truckers, a move industry executives warned could slow down supply chains that are already under stress. Canadian truckers who can’t show proof of vaccination will be required to quarantine when they re-enter the country from the U.S.

Shipping is expected to get disrupted in both directions, with the U.S. set to impose its own vaccine mandate on foreign travelers on Jan. 22. Only 50% to 60% of U.S. truckers are vaccinated, according to an estimate from the American Trucking Associations.

Bison Transport Inc., one Canada’s largest trucking firms, is poised to lose 10% of its freight capacity as a result, prompting the company to boost wages for cross-border drivers and offer signing bonuses of C$2,500 (about $2,000). Those costs have to be passed on to customers, Chief Executive Officer Rob Penner said.

“We understood that this would be a challenge for us,” Penner said in a Monday interview on BNN Bloomberg Television. “We have lost close to 10% of our overall capacity, with many drivers choosing to opt out prior to the deadline.”

Winnipeg, Manitoba-based Bison, which is owned by conglomerate James Richardson & Sons Ltd., has about 3,700 employees and contractors operating a fleet of 2,100 tractors and 6,000 trailers, according to its website.

There are already concerns large companies will be forced pay up to secure vaccinated drivers, pushing up freight costs, said Ron Lemaire, president of the Canadian Produce Marketing Association.

“I have heard anecdotally that truckers are looking to stop hauling perishable products as there are too many risks if they are delayed in their delivery,” Lemaire said by email, noting the association will be closely watching the impact on the supply chain.

Canadian importers rely on trucks to transport fruit that arrives from South America to ports in the northeastern U.S. A shortage of global containers and truck drivers is already causing shipping delays of as long as two weeks and having fewer available truckers will likely make things worse, said Larry Davidson, president of North American Produce Buyers Ltd. in Toronto.

The weekend before the vaccine mandate took effect, the company had only one truck available to pick up 75,000 boxes of grapes in Philadelphia, he said.

“Thirty-six of 37 loads that were ready for pickup had to wait four or five days,” said Davidson, whose company ships produce across Canada. “We’re seeing the domino effect just continue.” (link)

Fresh produce CANNOT sit on docks and distribution facilities for FOUR to FIVE days.

Remember what I said about fresh products and the importance of manufactured and processed foods?

Remember what I said about fresh products and the importance of manufactured and processed foods?

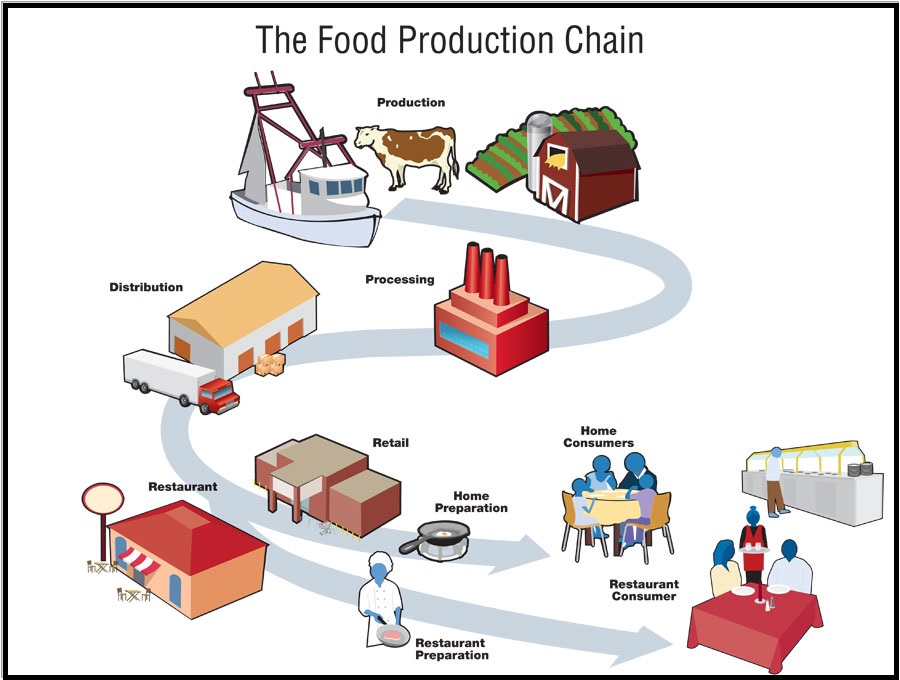

When fresh products start to become problematic, that ends up with a collapse on the other fork in the overall food supply-chain.

Pre-pandemic, retail grocery stores delivered about 40% of all food consumed, “food at home”, and restaurants, cafeterias, lunchrooms, bars, food trucks, fast food, hotels and other fresh-side venues delivered 60%.

The lockdowns, shutdowns, COVID restrictions and capacity rules shifted this food delivery dynamic to the reverse. We now have more than 60% food at home (grocery store) and less than 40% food away from home. That’s why the grocery store supply chains (including packaging) have been stressed from field to processing, to manufacturing, to suppliers, to distribution centers and to stores.

That retail side of the food equation has been working over capacity for almost two years. This shortage and capacity issue is what is compounding and driving inflation at the supermarket to levels we have never seen before….

Now, stop and think. The current trucker issue is going to not only hit the retail transportation side, but it is also going to hit the fresh side as we are in the time of year when we import fresh fruits and vegetables. Can you see the compounding issue now?

Stored food supplies (raw materials in frozen warehouses and deep cooled storage) are being drained by excess demand in manufacturing. Now fresh food supplies are being drained by a lack of rapid transportation that is absolutely critical.

FUBAR !

Resource Material: