This is a follow-up to the original explanation of the epicenter of the supply chain backlog issue, ie “The Clog“. {GO DEEP} You need to review the years-long and building background issue to understand the fubar that Joe Biden has just made worse.

From the White House perspective, the problem at the California ports, specifically the Port of Los Angeles (POLA) and the Port of Long Beach (POLB), was visible due to hundreds of container ships sitting in a queue off the coast of Los Angeles awaiting their opportunity to offload their cargo. The media was reporting on the backlog of ships and Joe Biden was under fire.

From the White House perspective, the problem at the California ports, specifically the Port of Los Angeles (POLA) and the Port of Long Beach (POLB), was visible due to hundreds of container ships sitting in a queue off the coast of Los Angeles awaiting their opportunity to offload their cargo. The media was reporting on the backlog of ships and Joe Biden was under fire.

The team behind Joe Biden wanted the optics removed asap. Hence, the White House meeting with the heads of the Ports of Los Angeles and Long Beach, Gene Seroka and Mario Cordero, respectively.

The continuing supply chain crisis of empty store shelves, missing parts and component goods that are backlogged at the California ports may be politically represented by the optic of those floating vessels. However, that’s not the problem.

The problem is a shortage of CA emission compliant internal transportation trucks to move the containers out of the port and into the U.S. mainland.

As a result… the politically expedient goal to get rid of the optical problem (the ships) by offloading containers into a California port system, that is already overwhelmed with tens-of-thousands of containers, is only making the original issue exponentially worse.

With hundreds more containers being offloaded hourly, the port infrastructure needed to load trucks long-sitting in the queue to pick up containers that arrived weeks ago is collapsing.

Truckers are waiting for over 8 hours to pick up their freight because the yards are swamped with containers. As each hour passes, more containers are offloaded into the port that can no longer deal with the scale of the problem. Each individual container is now buried in an avalanche of more containers, and that is making the limited compliant trucking resources even more problematic….. “containergeddon“.

Long before the ships started lining up offshore, many massive multinational corporations could foresee what was happening. They diverted their contracted freight into alternative ports (outside California) and began setting up new transportation arrangements. Two things happened:

(1) The alternative ports started getting backed up due to the redirected cargo arriving; and

(2) The shifted Trucking and Railroad system priority now meant resources were pulled from California.

With trucking companies redirecting resources away from California, this exacerbates the California backlog. Suppliers and retailers then enter a bidding war for priority distribution to get their stuff and avoid the clogs. This is a perfect storm of disruption in the supply chain aptly called “containergeddon.” However, not all ports can offload ships with thousands of containers. Not all ports have massive gantry cranes that can efficiently offload the cargo.

Back in California (where POLA and POLB do have the gantry cranes), now you have Los Angeles port workers saying we are offloading ships at maximum productivity, and truck drivers saying they’ve been sitting around for hours, some even days, waiting to pick up their containers. Meanwhile, other ports outside California are under pressure from the rerouted backlog of container vessels, and a limited amount of resources, trucks and railroad shipments to clear their arrivals.

Port workers are saying it’s not their lack of offloading that creates the problem, and the truckers are saying it ain’t us… “we’re sitting here waiting”.

♦ Few people are paying attention to what actually created the crisis in the first place.

The backlog all comes from California West Coast ports. It’s the issues with the new California emission regulations {Go Deep} that created the regional bottleneck in the distribution pipeline. The growing issue started becoming visible several months/years ago when the California Air Resource Board (CARB) announced the new environmental regulations.

As a direct result, several massive multinational corporations, with specifically concerned supply chain and logical operations specialists, immediately recognized the issue they would face if 50+ percent of the diesel fleet (writ large) would be blocked from entering California ports. That’s why months ago massive corporations began exclusive shipping contracts to avoid the California created crisis:

REUTERS – […] “The dry bulk cargo ship has been drafted into the service of retail giant Walmart, which is chartering its own vessels in an effort to beat the global supply chain disruptions that threaten to torpedo the retail industry’s make-or-break holiday season.

[…] Other big retail players, such as Target, Home Depot , Costco and Dollar Tree, have said they are chartering ships to deal with the … slowdown of sea networks that handle 90% of the world’s trade.” (link)

It costs more money, a lot more money, to move an entire supply chain for billions of tons of goods coming. The increases in shipping costs are passed along to the consumer.

Hence, we see prices climbing as a result of increased transportation costs being factored in to the new logistics. Did you hear about massive increases in container shipment prices? Well, THAT’S WHY.

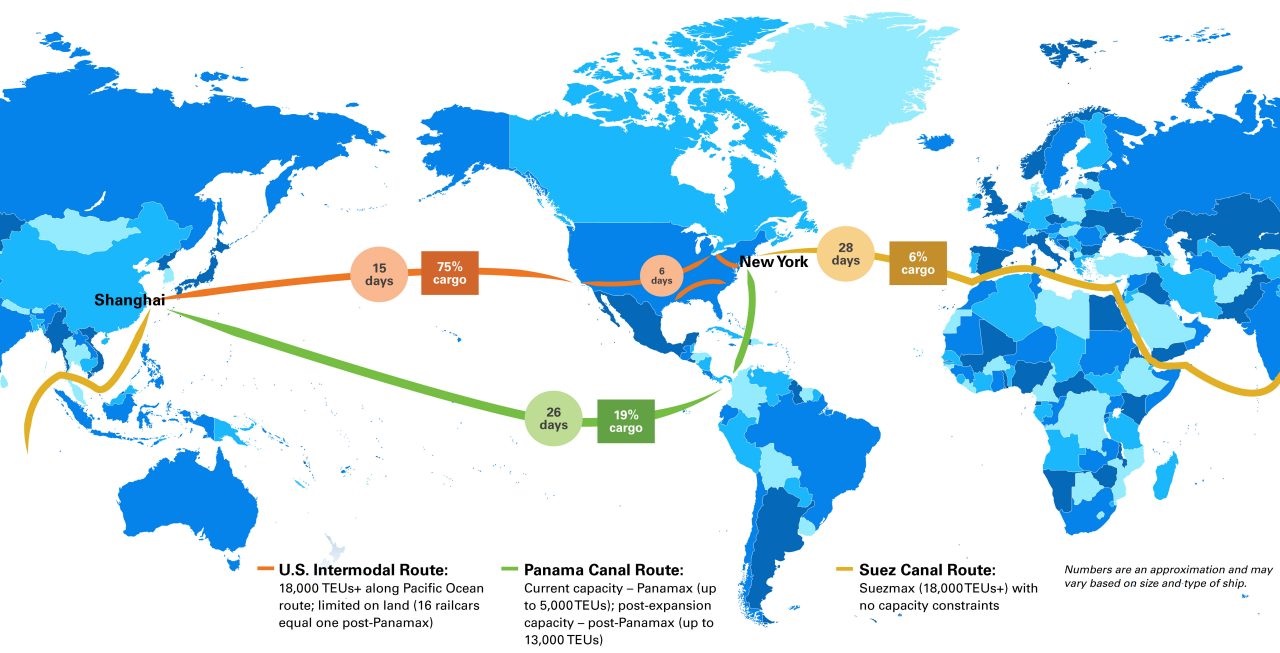

The entire supply chain from Asia to the United States was being modified from the closest port (California), which was cost effective, to the ports where internal transportation would not be an issue.

Ships from China and SE Asia were being diverted away from California, some through the Gulf of Mexico into Texas, Louisiana, Alabama ports or inland waterways. Some even headed to the East Coast. However, any shipment diverting from the West Coast has to go through the Panama Canal into the Gulf of Mexico. It takes twice as long and costs twice as much, if not more. Hence, massive shipping price increases per container.

Back in Washington DC, Joe Biden’s solution was to get rid of the ships floating off the coast of California by piling their cargo into Los Angeles ports that are already overwhelmed with cargo they are trying to organize. The emission compliant truck drivers are now charging the ports for their time sitting around waiting for the dock workers to locate their freight.

The more containers they pile into the port, the longer it takes a limited number of trucks to move them.

The California ports are running out of places to store containers full of goods that are getting off-loaded. Hundreds of thousands of them are piling up. The central issue is the inability of emission compliant heavy transportation in California to move those containers full of goods to manufacturing, warehouses and distribution points.

This California bottleneck has been building, and building and building for years, until now it has reached a crisis point.

FUBAR.